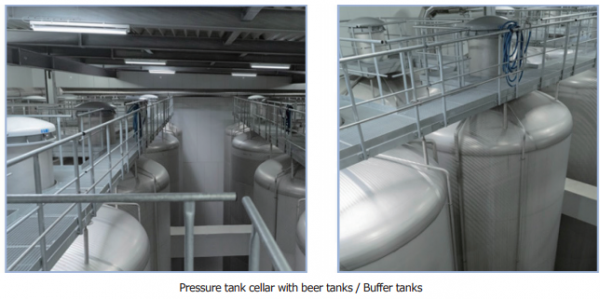

Feature Story Hydrostatic level measurement of buffer tanks in a brewery

페이지 정보

작성자 최고관리자 댓글 0건 조회 1,062회 작성일 24-05-14 19:16본문

- Reliable monitoring of brewed beer inventory prior to bottling

- Electronic differential pressure measurement on up to 17 m / 56 ft high cylindroconical stainless steel tanks

- Use of hygienic differential pressure transmitters without capillary tubing

1. Background

König Brewery, a wholly owned subsidiary of the Bitburger Brewery Group, produces a variety of beer in Duisburg, Germany. The "König Pilsener" beer, named after the founder, is still the brewery's flagship product today and is one of the best-known German beer brands.

Since the end of 2020 König Brewery has been brewing in a climate-neutral way. It has achieved this by primarily avoiding and reducing emissions. Residual emissions that are currently still technically unavoidable are being compensated for, and the company is constantly working on further optimising its processes at the site. This effort also included the commissioning of a new pressurized tank cellar in 2020. König Brewery planned and implemented this complete project in-house.

2. Measurement requirements

The pressure tank cellar is comprised of 20 cylindroconical stainless steel tanks. These are used as buffer tanks in which the bright beer is stored for bottling. The tanks are up to 17 m / 56 ft high and have a capacity of up to 2000 hectolitres / ~53 thousand US gallons. For the inventory management of beer quantities, the brewery needed reliable level monitoring.

Initially, they planned to implement traditional differential pressure measurement on the tanks. However, due to the large size and filling height of the tanks, this turned out to be unfeasible. Given the difference in height between the installation of the pressure transmitter and the lower process connection, the pressure of the filling fluid in the capillary tubing would have fallen below the vapour pressure. This would cause the liquid column to collapse. This effect limits the maximum length of remotely mounted capillary tubes in relation to the filling liquid.

3. KROHNE solution

The OPTIBAR 5060 eDP electronic differential pressure transmitter offered a powerful and reliable alternative to mechanical differential pressure measurement. It consists of two single gauge pressure trans-mitters, which are connected to each other as primary and secondary transmitter by an electronic signal cable. For ease of access, the primary transmitter is mounted in a tank nozzle at the top of the tank, right next to a pressure and vacuum relief valve. It measures the gas pressure in the tank. The secondary transmitter is located at the conically shaped bottom of the tanks. It measures the overall hydrostatic pressure in the tank and transmits the measured value to the primary transmitter and it calculates the net differential pressure from both measuring signals.

Since this electronic differential pressure measurement device works without capillary tubes, it could therefore be used with the plant’s existing tank heights. Unlike conventional differential pressure measurement with diaphragm seals, installation with significantly smaller process connections was possible. Both the primary and secondary transmitters were equipped and mounted with hygienic connections.

The OPTIBAR 5060 eDP is equipped with a fully welded stainless steel diaphragm. Since the diaphragm weld seams are outside of the wetted sealing face, there is no contact between the process medium and the less corrosion-resistant weld seam nor the material transition of the diaphragm to the base material. This provides increased protection against corrosion and leakage. The pressure-bearing fill fluid in the transmitters meets the requirements of the food industry. Alternatively, a ceramic diaphragm without fill fluid is also available for those applications. In accordance with customer requirements, KROHNE provided the OPTIBAR 5060 eDP with an electropolished stainless-steel housing. The primary transmitter sends the readings to the brewery's control room via Profibus PA.

4. Customer benefits

The use of the OPTIBAR 5060 eDP contributes to reliable inventory management of the buffered beer quantities. The brewery operator monitors the buffer tanks via the control system and thus maintains a central overview of all available beer inventories. The company can now optimally plan and use the available buffer capacities. In this way, the lengthy brewing procedures, which can last several weeks, can be perfectly matched with the fast-moving bottling processes, which only take a few hours. Compared with conventional differential pressure measurement using capillary tubes with fill oil, electronic differential pressure meaure-ment offered a highly reliable solution that could be flexibly installed throughout the plant. The primary transmitter was even able to be mounted on top of the tank.

The OPTIBAR 5060 eDP is just one of several process measurement instruments that KROHNE provided to equip the bright beer tank cellar. The scope of supply also included electromagnetic flowmeters, temperature sensors and capacitive level switches.

5. Product used

OPTIBAR PM 5060 eDP

- Electronic differential pressure transmitter as an alternative to conventional diaphragmseal installations

■ Contact: KROHNE

+82-2-782-1900 / www.krohnekorea.com